Who we are

Tech. Lic. M. Sc. Luis Lopez Martinez, LETS Global AB

Luis Lopez Martinez received his M.Sc. Naval Architecture from the KTH – Royal Institute of Technology in Stockholm, Sweden in 1986. He went on and received his Licentiate Engineering degree within Fatigue Behavior of Welded High-Strength Steels while working at the Application Research Development at Swedish Steel Oxelosund, Sweden. After have been working for mayor companies such as Swedish Steel, Kvaerner Oil & Gas, TWI and Atkins Oil & Gas Luis decided to put all the knowledge he gathered through the years by starting his own engineering company dedicated to the Life Extension and Structural Integrity of Offshore Structures.

Approved by Leading Classification Societies

For over two decades, LETS Global has led the introduction and practical implementation of Ultrasonic Peening Technology (UPT) in the offshore industry. Today, ultrasonic peening is an established and trusted method for enhancing the fatigue life of critical welded structures exposed to the demanding offshore environment.

LETS Global Ultrasonic Peening stands as the benchmark for offshore applications, being endorsed by the world’s leading classification societies — DNV, ABS, Lloyd’s Register, Bureau Veritas, ClassNK, and RINA.

Introduction

Since the early 2000s, LETS Global has been the sole and pioneering provider of ultrasonic peening technology applied offshore onsite. Through continuous innovation and validation under classification society supervision, LETS Global has set the global benchmark for fatigue life improvement and life extension of welded structures in offshore assets. Ultrasonic peening remains today the only recognized and approved technology for offshore onsite fatigue life enhancement.

Chronological Development and Validation (2005–2010)

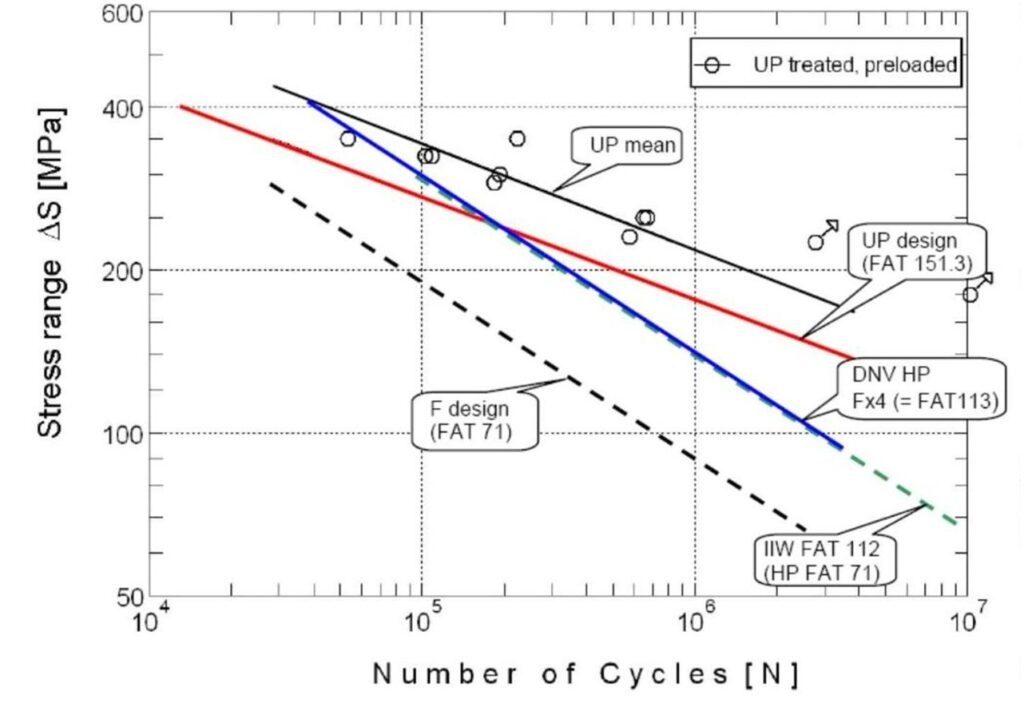

Between 2005 and 2009, LETS Global conducted comprehensive fatigue testing programs in Norway and Sweden. These programs simulated offshore loading conditions and confirmed that ultrasonic peening preserves its improvement effect even under severe fatigue stress relaxation scenarios. The findings were presented at the Fatigue Design Conference 2009 (CETIM, France), establishing LETS Global as the pioneer in ultrasonic peening validation under classification society oversight.

This research demonstrated a four-to-ten-fold increase in fatigue life compared to untreated welded joints. It became the foundation for classification society acceptance and later formal approval by Lloyd’s Register.

Fatigue Test Results (LETS Global, Fatigue Design 2009)

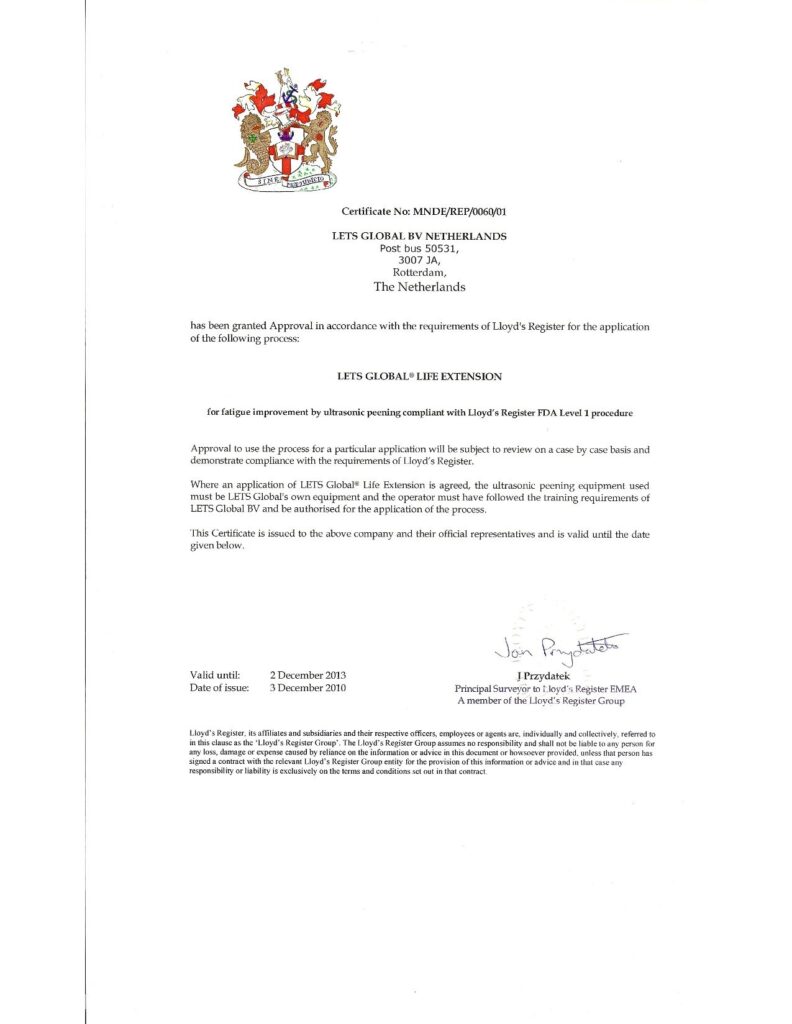

Lloyd’s Register Approval (2010)

In December 2010, Lloyd’s Register issued the first-ever Approval in accordance with the FDA Level 1 procedure for the LETS Global® Life Extension Process using Ultrasonic Peening for fatigue improvement. This landmark certification made LETS Global the first and only company worldwide authorized to conduct ultrasonic peening offshore onsite under classification society supervision.

Recognition by Major Classification Societies (2011–2020)

Following Lloyd’s Register’s approval, other classification societies progressively recognized Ultrasonic Peening as an effective post-weld fatigue improvement method. LETS Global’s procedure has been referenced and accepted in standards and guidelines by leading societies, including:

– DNV (Det Norske Veritas) – Recognized under DNV-ST-F101 and DNV-RP-C203 as a post-weld treatment for fatigue life enhancement.

– ABS (American Bureau of Shipping) – Includes Ultrasonic Peening within life extension methodologies for offshore installations.

– Bureau Veritas (BV) – Referenced in NR426: Fatigue Assessment of Ship Structures.

– Lloyd’s Register (LR) – Continuous inclusion in fatigue improvement guidelines.

– ClassNK (Nippon Kaiji Kyokai) – Acceptance of Ultrasonic Peening for fatigue life improvement of welded joints.

– RINA (Registro Italiano Navale) – Reference in fatigue design and maintenance recommendations.

Excerpt from Lloyd’s Register Certificate (2010)

Timeline of Progressive Acceptance

2005–2009: Laboratory validation and fatigue testing (Norway & Sweden)

2009: Presentation at Fatigue Design Conference (CETIM, France)

2010: Lloyd’s Register formal approval (FDA Level 1 Procedure)

2011–2020: Recognition by DNV, ABS, BV, ClassNK, and RINA

2020–2025: Continued application and leadership in offshore onsite Ultrasonic Peening

Present Status and Continuing Leadership (2020–Present)

Today, LETS Global remains the world’s only company performing offshore onsite Ultrasonic Peening under approved classification society procedures. The technology continues to extend the lifespan of offshore oil, gas, and wind structures efficiently and sustainably. LETS Global’s commitment to research and continuous improvement keeps it at the forefront of fatigue life enhancement technologies.

References

- Lloyd’s Register Certificate No. MNDE/REP/0060/01 – Approval of LETS Global® Life Extension Process (2010–2013).

- Lopez Martinez L., Validation by Classification Societies of LETS Global® Life Extension Procedure for Offshore Installations, Fatigue Design Conference 2009, CETIM France.

- DNV-ST-F101 and DNV-RP-C203 – Fatigue Design of Offshore Steel Structures (https://www.dnv.com).

- ABS Guidance Notes on Life Extension Methodologies (https://www.eagle.org).

- Bureau Veritas NR426 – Fatigue Assessment of Ship Structures (https://marine-offshore.bureauveritas.com).

- ClassNK Guidelines for Fatigue Strength Improvement Methods (https://www.classnk.or.jp).

- RINA Rules for the Classification of Ships – Part C (https://www.rina.org).