Replacement of PWHT

Replacement of PWHT

Residual stresses originating from weld induced thermal variations and metallurgical phase transformations have a negative influence on the fatigue performance of welded components and structures. A normal way to get rid of these and to decrease their negative influence on fatigue endurance is the application of post weld heat treatment. However, this method have a number of disadvantages among others: costs, difficulties when dealing with big steel structures, damaging of strength/toughness properties of parent plate if not accurate temperature and time sequences are applied among others. High-strength steels are tempered at certain temperature and if that specific temperature is exceed the parent plate properties could be damaged so it is paramount that PWHT temperature keep under strict control.

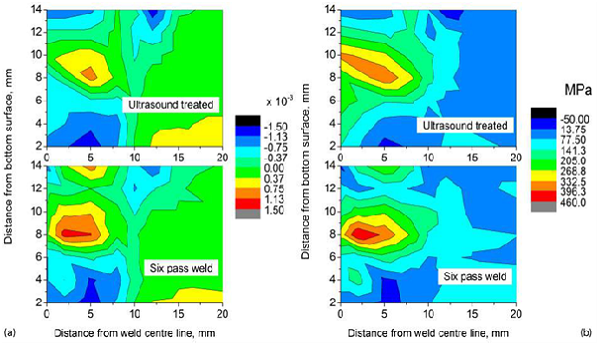

The ultrasonic peening treatment introduces compressive stresses which counteract the by the welding induced tensile stresses. This is possible without any increase in temperature and could be applied locally in the structure.

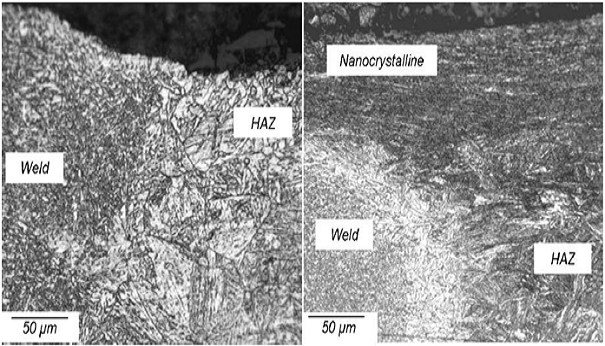

Influence of ultrasonic peening treatment on welding residual stresses on a) stress and b) strain; Gao et al.; Stress Relaxation; Science and Technology of welding and joining, 2014, Vol 19, No 6, pp. 510

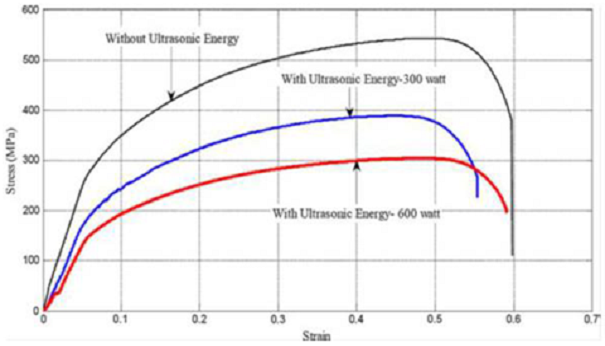

Stress-strain curves of tensile specimen with and without ultrasonic vibration; Shalvandi et al.; Influence of ultrasonic stress relief on SS316; Mater. Des. 2013, 46, pp 713-723