Design Optimization

Design Optimization

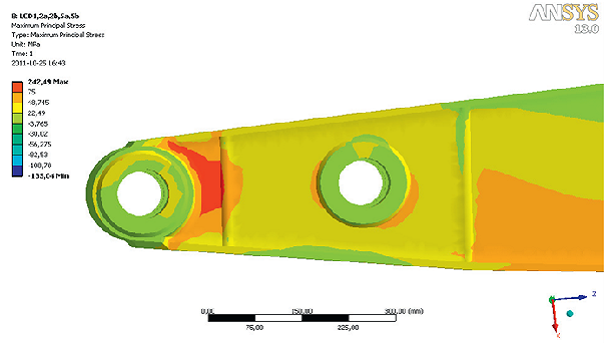

An optimization problem is a problem in which certain parameters or design variables ( required fatigue strength ) need to be determined in order to achieve the best and measurable performance (desired endurance) under given constraints (minimize the weight of an excavator arm). In our particular case, we consider the fatigue strength of a specific and optimized weld configuration as the measurable design variable. This is of course under the assumption any other structural design variables as buckling, wear resistance, etc. are keep under control.

Under such circumstances it will be the fatigue strength of the specific welded joint which will govern the overall structural integrity and therefore an improvement of the endurance of these welds by ultrasonic peening treatment will produce an overall enhancement of the structural integrity. That is the general case for any fatigue life extension measure implemented in order to extend the service life of an existing structure.

When dealing with new design and specifically design of structures using high strength steel or high strength aluminium the enhancement of welds subjected to fatigue loads will either extend the service life or allow for the decrease of plate thickness which in both cases will imply a cost reduction. However, Design Optimization requires certain compulsory steps to be followed:

Design: the determination of design parameters which will lead to the best performance or best compromise strength/fatigue.

Planning: production planning that is keeping manufacturing costs at the lowest possible level.

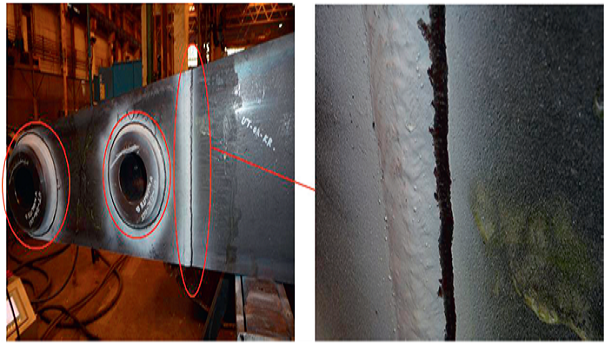

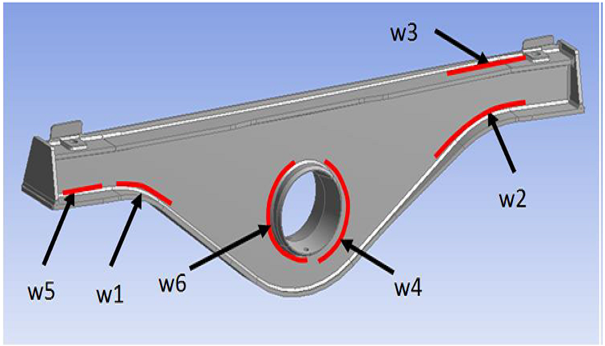

Control and Manufacturing: For this specific optimization problem it will be the quality control of weld geometrical parameters both during welding procedure and ultrasonic peening treatment.

Submodels of fatigue sensitive welds, Jonssson et al. Procodia Engineering 66 (2013) 202-215

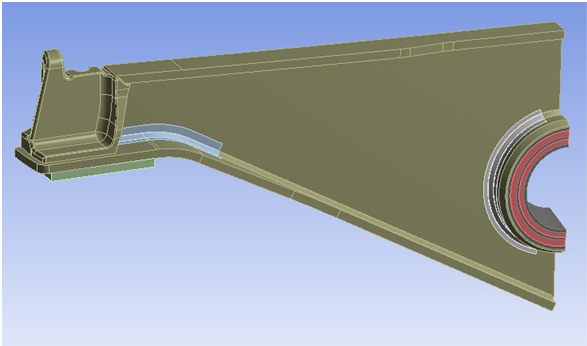

Ultrasonic peening treated weld in optimized model, Ibidem

Principal stresses in the current design, Ibidem