Design Optimization

Design Optimization

An optimization problem arises when certain parameters or design variables—such as the required fatigue strength—must be defined in order to achieve the best measurable performance (e.g., desired endurance) under given constraints (e.g., minimizing the weight of an excavator arm). In our case, we focus on the fatigue strength of a specific, optimized weld configuration as the key measurable variable. This assumes that other structural aspects, such as buckling, wear resistance, and general stability, are maintained within safe limits.

Under these conditions, the fatigue strength of the welded joint becomes the decisive factor for overall structural integrity. Enhancing the endurance of these welds—such as through ultrasonic peening treatment—directly improves structural reliability and extends service life. This principle applies broadly to any fatigue life extension strategy aimed at increasing the longevity of existing structures.

For new designs, particularly those employing high-strength steel or high-strength aluminum, improving weld fatigue performance delivers two major benefits:

- Extended service life, reducing downtime and maintenance costs.

- Reduction in plate thickness without compromising safety or durability.

Both outcomes result in significant weight savings, which not only reduce raw material consumption but also lower energy demand during operation. These weight reductions positively influence the energy transition, since lighter, more efficient machines consume less fuel or electricity. Additionally, reduced material use translates into environmental savings (lower CO₂ emissions from steel/aluminum production) and better material resource efficiency.

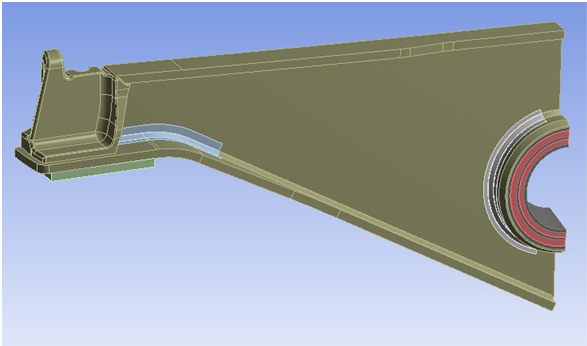

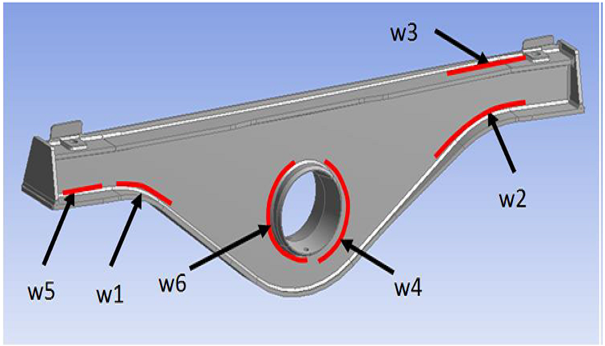

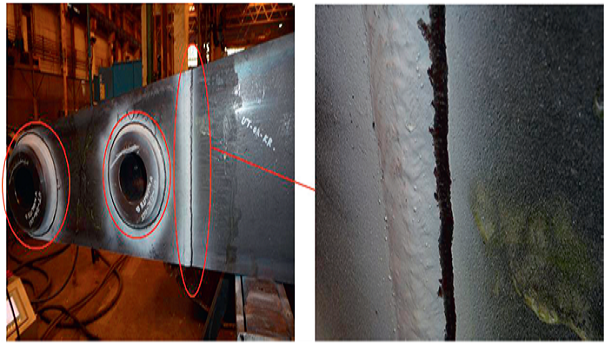

Submodels of fatigue sensitive welds, Jonssson et al. Procodia Engineering 66 (2013) 202-215

Ultrasonic peening treated weld in optimized model, Ibidem

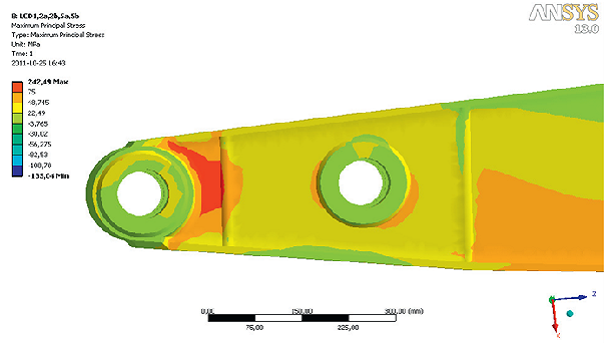

Principal stresses in the current design, Ibidem

Ultrasonic peening treated weld, Ibidem.

Technical Perspective (Engineering Focus)

From a technical standpoint, the optimization process requires systematic steps:

- Design: Define parameters balancing strength and fatigue resistance for maximum efficiency under given loads.

- Planning: Develop manufacturing and assembly methods to minimize cost while achieving target tolerances.

- Control & Manufacturing: Ensure precise quality control of weld geometry and apply ultrasonic peening treatment consistently to achieve repeatable fatigue life improvement.

Here, the fatigue strength of the weld is the governing variable. Any improvement in this parameter increases the structure’s resistance to cyclic loads, which either extends service life or enables weight reduction by using thinner plates.

Management & Strategy Perspective

For management, the key outcomes of this optimization are:

- Cost savings: Reduced material input and extended product life lower both production and lifecycle costs.

- Sustainability benefits: Weight reduction leads to lower CO₂ emissions in both material production and machine operation, contributing directly to corporate sustainability targets and energy transition goals.

- Competitive advantage: More efficient, longer-lasting products strengthen market position, particularly as regulations and customers increasingly demand greener, resource-efficient solutions.

Short Example with Economical Aspects

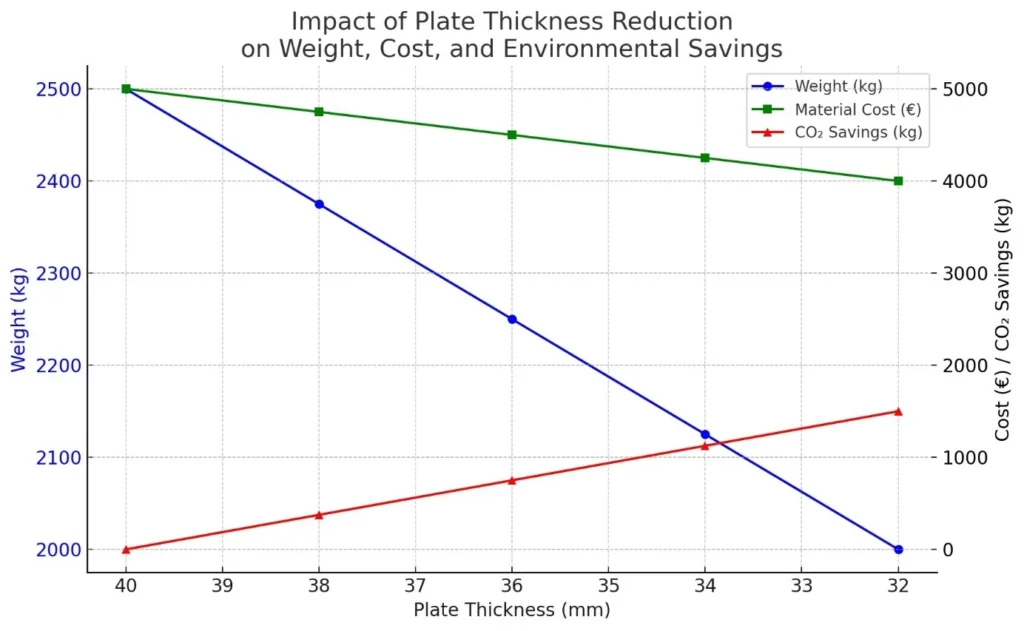

Consider the design of an excavator arm made from high-strength steel. Without weld optimization, the design requires a plate thickness of 40 mm to ensure sufficient fatigue life. By applying ultrasonic peening, the fatigue resistance of the welds increases by ~25%, allowing the plate thickness to be reduced to 32 mm while maintaining equivalent durability.

- Weight savings: ~20% reduction in plate weight (e.g., from 2,500 kg to 2,000 kg per arm).

- Material cost savings: At ~€2.0/kg for high-strength steel, this saves €1,000 per arm.

- Operational savings: The 500 kg lighter arm reduces fuel consumption by ~2% during machine operation, leading to ~€5,000 in fuel savings over a 10-year service life.

- Environmental benefit: ~1.5 tons of CO₂ avoided in steel production and ~15 tons avoided from reduced fuel consumption.

This example illustrates how weld optimization combines technical improvements (fatigue strength, structural integrity) with economic and environmental benefits (cost reduction, energy transition contribution, and resource efficiency).