How Ultrasonic Impact Treatment (UIT) Extends FPSO Asset Life — Safely, Sustainably, and With Classification Approval

Fatigue damage is one of the most persistent integrity challenges affecting Floating Production Storage and Offloading units (FPSOs). Operating continuously under cyclic wave loading, production stresses, and harsh marine environments, FPSO structures are particularly vulnerable to fatigue cracking at welded joints.

Extending FPSO asset life safely and cost-effectively requires proactive fatigue mitigation. Ultrasonic Impact Treatment (UIT), often referred to in industry literature as ultrasonic peening, is a classification-approved solution that addresses fatigue at its root cause and can be applied offshore on operational FPSOs.

1. The Reality of FPSO Fatigue Risk

FPSOs are exposed to millions of stress cycles over their service life. Fatigue cracks typically initiate at weld toes, structural discontinuities, and areas with tensile residual stress from fabrication. Early-stage fatigue cracks are often undetectable by routine inspection and may grow unnoticed for years [1].

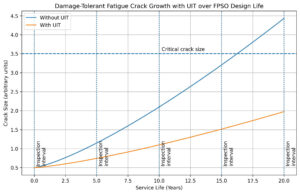

Figure 1. Damage-Tolerant Fatigue Crack Growth with UIT Over FPSO Design Life

By reducing fatigue crack growth rates, UIT maintains sub-critical crack sizes at all inspection intervals, preserving fracture margin and enabling uninterrupted FPSO operation over a 20-year service life.

2. Why Traditional Reinforcement Isn’t Always Enough

Conventional fatigue management strategies such as steel plating, weld repair, and local reinforcement often require hot work and offshore downtime. In addition to not relieving the existing tensile residual stress field, these interventions typically introduce new and largely uncontrolled residual stresses associated with welding and fabrication. Weld repairs may also generate additional geometric discontinuities, micro-defects, and local stress risers at or adjacent to the repaired detail. Importantly, such measures do not alter the cyclic stress range experienced by the structural detail during each loading cycle, which remains governed by the global structural response. As a result, fatigue cracks may re-initiate at or near the repair location, and the fatigue performance of the repaired detail is generally not improved beyond the original design intent and may in practice be reduced if stress concentrations are increased. It is therefore strongly recommended that any weld repair be followed by the application of Ultrasonic Impact Treatment (UIT), as UIT directly addresses the underlying contributors to fatigue damage by modifying the weld toe geometry, introducing beneficial compressive residual stresses, and mitigating crack initiation and propagation mechanisms..

3. Ultrasonic Impact Treatment — What It Really Does

Ultrasonic Impact Treatment (UIT) introduces beneficial compressive residual stresses at welded joints while forming a controlled weld toe groove. This reduces local stress concentration and significantly improves resistance to fatigue crack initiation and propagation [2,4].

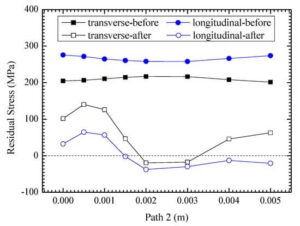

The effectiveness of Ultrasonic Impact Treatment (UIT) in improving fatigue performance is directly linked to its ability to modify the residual stress state at welded joints. Figure 2 presents experimentally measured residual stress distributions at a welded joint in the as-welded condition and after the application of UIT. In the as-welded state, high tensile residual stresses are present at the weld toe, which are known to accelerate fatigue crack initiation and propagation. Following UIT, these tensile stresses are significantly reduced and locally replaced by compressive residual stresses. This stress-state transformation in combination with the introduction of the weld toe grove, delays crack initiation and reduces crack growth rates under cyclic loading, providing a clear mechanistic explanation for the observed fatigue life extension achieved with UIT [3]

Figure 2. Measured residual stress distribution at a welded joint before and after Ultrasonic Impact Treatment (UIT).

X-ray diffraction measurements show the transition from high tensile residual stresses in the as-welded condition to reduced and locally compressive residual stresses after UIT application. The measurements are taken along defined paths at the weld toe, demonstrating the stress-relief and compressive stress-inducing effect of UIT. Adapted from Chen et al. [3], Materials (2020), under CC BY 4.0.

4. CAPEX vs OPEX — Quantifying the Value of Proactive Fatigue Mitigation

From an asset integrity and lifecycle perspective, the primary financial benefit of proactive fatigue mitigation lies in the avoidance of unplanned failure, rather than the cost of the intervention itself. Traditional reactive repair strategies are typically triggered late in the fatigue damage process, when cracks have already reached significant size and operational flexibility is limited. This often results in high capital expenditure, operational disruption, and cost uncertainty.

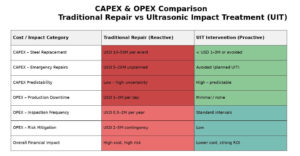

By contrast, Ultrasonic Impact Treatment (UIT) enables fatigue mitigation to be performed in a planned, targeted manner, reducing both CAPEX exposure and ongoing OPEX. Table 1 provides a qualitative and indicative cost comparison between traditional reactive repair approaches and proactive UIT intervention for FPSO structures.

Table 1. Indicative CAPEX and OPEX comparison between traditional reactive repair strategies and proactive Ultrasonic Impact Treatment (UIT) intervention for FPSO structures.

The table illustrates typical cost ranges and operational impacts associated with fatigue management approaches. Traditional reactive repairs are characterized by high and uncertain capital and operational expenditure, while proactive UIT intervention enables predictable costs, avoided failures, and reduced lifecycle expenditure. Cost ranges are indicative and depend on FPSO size, location, and operational constraints.

5. Conclusion — Why Avoided Failure Drives the Business Case

The economic case for UIT is not driven by marginal savings on individual repairs, but by the avoidance of the most expensive outcomes: unplanned shutdowns, emergency offshore campaigns, and large-scale steel replacement. From a lifecycle cost perspective, a single avoided failure event can justify multiple UIT campaigns.

When combined with its technical benefits — reduced fatigue crack initiation, slower crack growth, and preserved fracture margins — UIT represents a low-risk, high-return strategy for FPSO operators seeking to extend asset life while maintaining safety, compliance, and operational continuity.

6. References

[1] DNV-RP-C203, Fatigue Design of Offshore Steel Structures, DNV.

[2] International Institute of Welding (IIW), Guidelines for Ultrasonic Impact Treatment (UIT).

[3] Chen, X., et al., Experimental and Numerical Simulation to Study the Reduction of Welding Residual Stress by Ultrasonic Impact Treatment, Materials, 13(4), 837, 2020.

[4] Schijve, J., Fatigue of Structures and Materials, Springer.

[5] Classification Society Approved Offshore UIT Procedures, LETS Global.