Life Extension Engineering

Semisubmersibles and fatigue life extension

Semisubmersibles and fatigue life extension

A large number of semisubmersible drilling rigs are approaching, or have already reached, their original design service life.

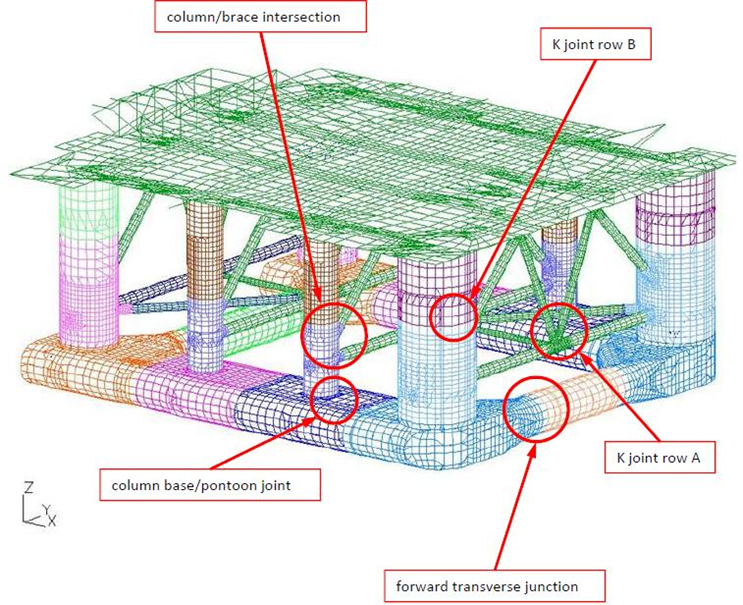

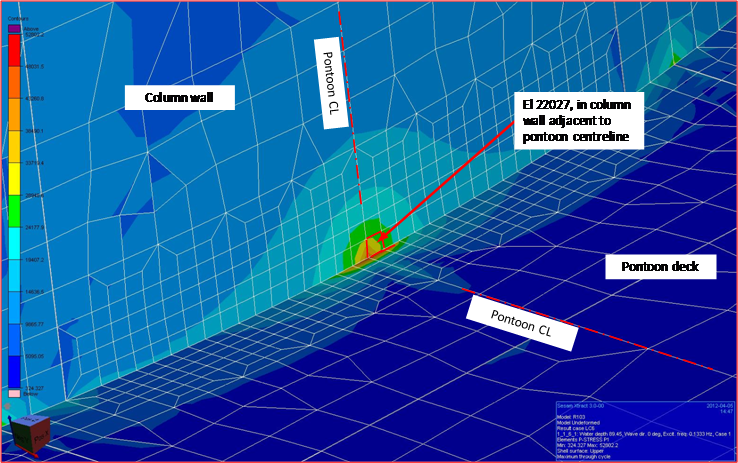

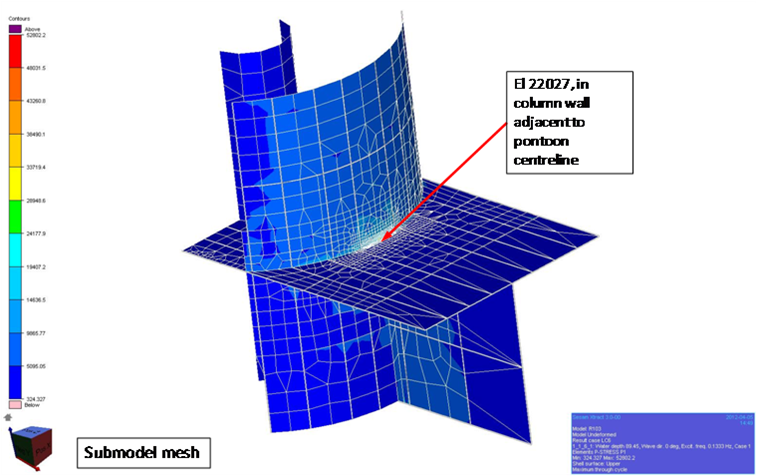

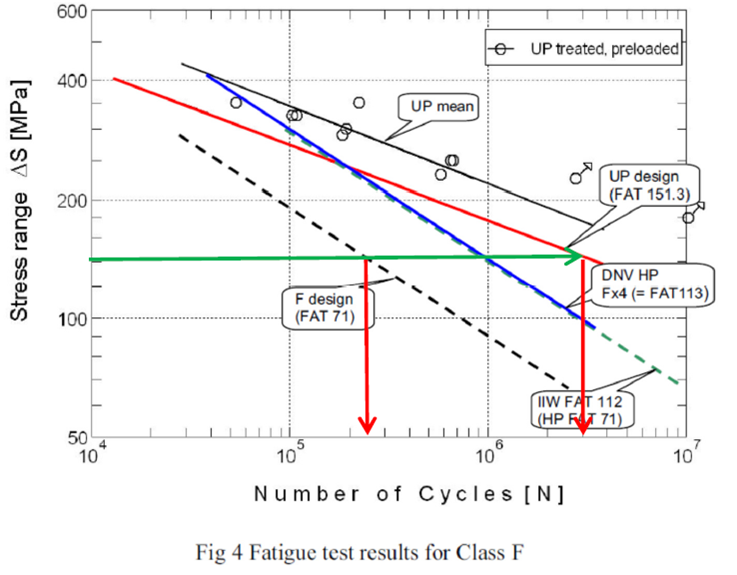

In many cases, shipyards built entire series of rigs based on similar drawings, meaning that fatigue hot spots identified on one unit will often correspond to nearly identical locations on its sister rigs. To enable continued safe operation, updated finite element analyses (FEA) are needed to accurately identify and assess fatigue-sensitive hot spots. Once located, these areas can be treated with established fatigue life improvement techniques, allowing for the extension of the rig’s operational life.

Classification societies typically recommend operators apply fatigue life improvement methods that enhance fatigue resistance and ensure long-term structural integrity. The most fatigue-sensitive areas on semisubmersibles include the main columns, their connections to pontoons, brace-to-column joints, internal brace welds, and flare towers. Such works are generally scheduled during regular maintenance stops, making life extension an economically efficient intervention.

Relevant Stress Ranges for Fatigue Life Extension

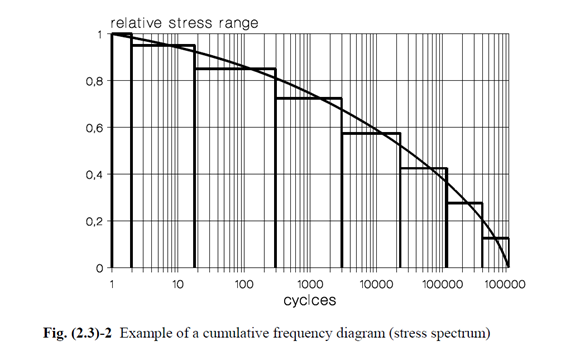

The stress ranges relevant to fatigue life extension have been derived from exceedance probability and accumulated exceedance diagrams, accounting for long-term stress distributions. With a Weibull shape parameter of approximately h ≈ 1.0, the majority of fatigue damage is concentrated around 10 million cycles. About half the total damage occurs below this threshold, and half above.

Value of Fatigue Life Extension

Extending the fatigue life of semisubmersibles provides triple value:

1. Energy Transition Contribution – By extending service life by 20 years, operators can repurpose rigs for low-carbon applications such as offshore wind installation support, subsea infrastructure work, or carbon capture and storage projects.

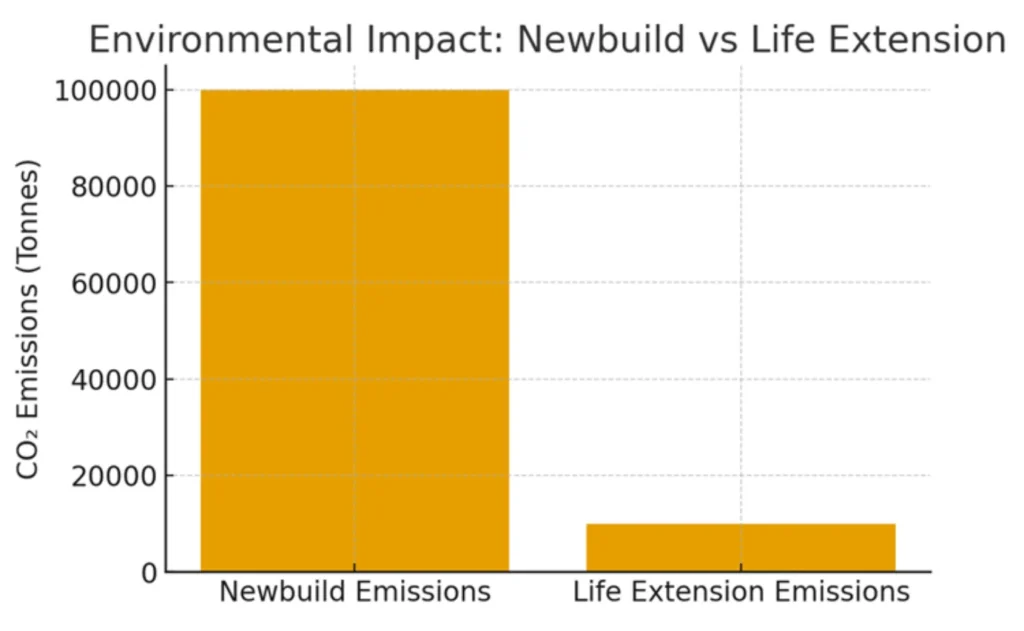

2. Environmental Savings – Building a new semisubmersible requires approximately 40,000–60,000 tonnes of steel and generates over 100,000 tonnes of CO₂ emissions. Extending service life avoids these emissions, equivalent to the annual emissions of ~20,000 passenger cars.

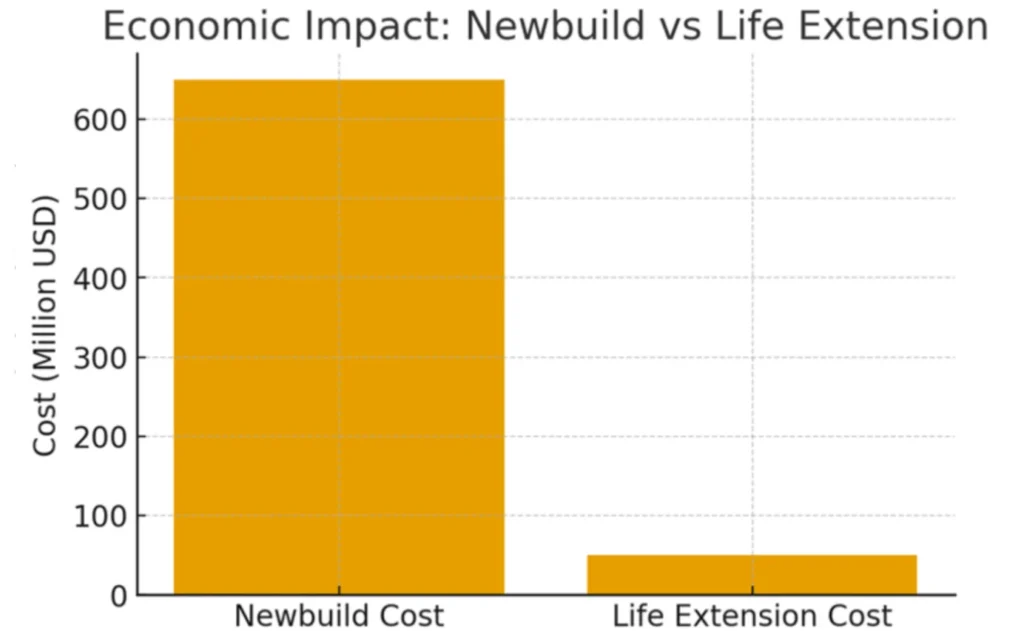

3. Economic Impact – A modern semisubmersible costs USD 600–700 million new, while life extension costs USD 30–50 million. Extending life instead of building new saves USD 550–650 million per unit. For a fleet of 10 rigs, total savings exceed USD 6 billion, while avoiding more than 1 million tonnes of CO₂ emissions.

Conclusion

Fatigue life extension of semisubmersibles is no longer just a matter of structural safety and economic efficiency—it has become a strategic enabler for the energy transition. By avoiding newbuild emissions, reducing capital requirements, and enabling repurposing of existing offshore assets, fatigue life extension represents one of the most cost-effective and sustainable solutions available to the offshore industry today.