Replacement of PWHT

Ultrasonic Peening as an Alternative to Post-Weld Heat Treatment: Enhancing Fatigue Life and Reducing Costs

Residual Stress Management in Welded Structures

How Ultrasonic Peening Replaces Heat Treatment for Safer, Stronger, and More Sustainable Structures

1. Understanding Residual Stresses

During welding, intense thermal cycles and phase transformations generate complex residual stress fields. As the weld metal cools and contracts, tensile residual stresses develop in and around the weld and the heat-affected zones (HAZ).

These tensile stresses are among the main drivers of fatigue cracking, which can significantly reduce the fatigue endurance and service life of welded joints and components. Managing or neutralizing these stresses is essential for safe, long-life structural performance, especially in offshore, energy, and transport applications.

2. Traditional Solution: Post-Weld Heat Treatment (PWHT)

Post-Weld Heat Treatment (PWHT) is the conventional technique used to relieve residual stresses. It involves reheating the welded component to a specific temperature, holding it for a defined period, and then cooling it under controlled conditions.

While effective, PWHT presents several limitations:

- High cost and energy consumption

- Difficult implementation on large or complex steel structures

- Potential loss of strength and toughness in the base material if temperature or time are not precisely controlled

For high-strength steels, these issues are even more critical. Such steels are pre-tempered during production, and exceeding their tempering temperature during PWHT can permanently damage mechanical properties. Maintaining precise thermal control in field conditions is technically demanding and expensive.

3. Modern Alternative: Ultrasonic Peening (UP)

Ultrasonic Peening (UP) offers a mechanical, non-thermal alternative to PWHT. Instead of using heat, the process employs high-frequency mechanical impacts that reshape the surface layer of the weld and introduce beneficial compressive residual stresses.

How It Works

- High-frequency vibrations accelerate small impact pins against the weld surface.

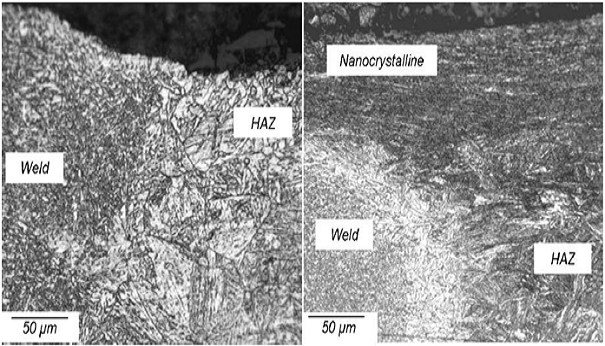

- Each controlled impact produces localized plastic deformation, refining surface grains and generating compressive stresses that counteract existing tensile stresses.

- The treated surface becomes smoother and more resistant to fatigue crack initiation.

4. Key Advantages of Ultrasonic Peening

No Heat, No Risk

No thermal exposure means no microstructural degradation or tempering effects—making it ideal for high-strength steels.

Immediate Fatigue Improvement

Fatigue life can increase by two to ten times, depending on the joint type and loading conditions.

Field-Ready and Scalable

Compact, air-cooled systems allow treatment of large structures such as offshore platforms, bridges, and wind-energy towers.

Cost- and Energy-Efficient

Requires only electrical power and compressed air—no furnaces, no heating, and minimal downtime.

Sustainable and Low-Carbon

Extends the life of existing assets, reducing the need for new fabrication and lowering the overall carbon footprint.

5. Summary: A Smarter Way to Strengthen Welded Structures

| Aspect | PWHT | Ultrasonic Peening |

|---|---|---|

| Process Type | Thermal | Mechanical (non-thermal) |

| Energy Use | High (furnace or induction) | Low (electric/air) |

| Material Impact | Risk of over-tempering | Preserves base-metal properties |

| Scalability | Difficult for large structures | Portable and field-applicable |

| Sustainability | High carbon footprint | Life-extension with minimal emissions |

Ultrasonic Peening at LETS Global

At LETS Global, ultrasonic peening is more than a surface-treatment technology—it is a strategic tool for structural life extension and sustainability. By introducing controlled compressive stresses without heat, LETS Global helps clients extend asset life, reduce maintenance costs, and minimize environmental impact.

The company’s latest generation of robotic and digitally monitored HFMI systems ensures repeatable quality and full traceability. These systems integrate seamlessly with structural integrity monitoring platforms and AI-driven predictive models, enabling intelligent maintenance planning across the full lifecycle of critical infrastructure.

| Feature | Ultrasonic Peening (UP) | Post-Weld Heat Treatment (PWHT) |

|---|---|---|

| Temperature Requirement | None | High (typically 590–800°C) |

| Energy Consumption | Low | High |

| Processing Time | Short (<1 hour) | Long (several hours to days) |

| Equipment Cost | Moderate | High (furnaces, insulation, etc.) |

| Applicability to Large Structures | High (portable equipment) | Limited (requires large furnaces) |

| Effect on Material Properties | Preserved | Potential degradation if not controlled |

| Fatigue Life Improvement | Significant | Moderate to significant |

Economic Considerations

The economic advantages of UP over PWHT are evident in several aspects:

- Energy Savings: UP eliminates the need for heating large volumes of material, leading to substantial energy cost reductions.

- Reduced Processing Time: The rapid application of UP allows for shorter turnaround times, increasing throughput and reducing labor costs.

- Lower Equipment and Maintenance Costs: UP equipment is generally more affordable and requires less maintenance compared to the complex infrastructure needed for PWHT.

For instance, a comparative study on I-beam components subjected to fatigue loading demonstrated that UP not only improved fatigue life but also resulted in lower overall treatment costs compared to traditional PWHT methods. ResearchGate

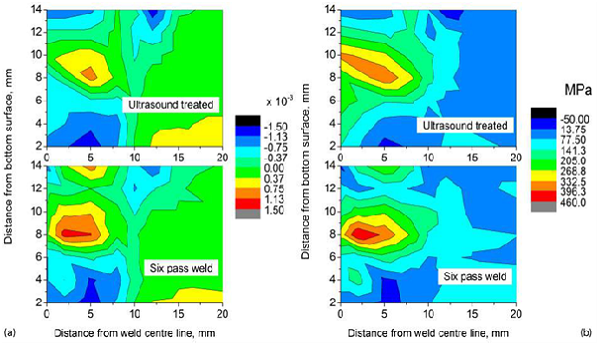

Influence of ultrasonic peening treatment on welding residual stresses on a) stress and b) strain; Gao et al.; Stress Relaxation; Science and Technology of welding and joining, 2014, Vol 19, No 6, pp. 510

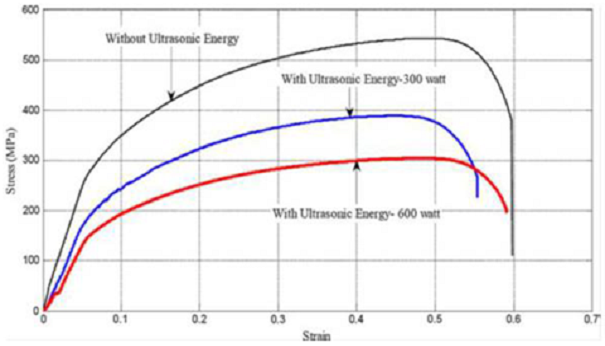

Stress-strain curves of tensile specimen with and without ultrasonic vibration; Shalvandi et al.; Influence of ultrasonic stress relief on SS316; Mater. Des. 2013, 46, pp 713-723

Conclusion

Ultrasonic Peening presents a viable and economically advantageous alternative to Post-Weld Heat Treatment for enhancing the fatigue life of welded structures. Its ability to introduce beneficial compressive residual stresses without the need for thermal energy makes it particularly suitable for high-strength materials and large-scale applications. Adopting UP can lead to significant cost savings, improved material performance, and increased operational efficiency in industries where welded components are prevalent.