FPSO

FPSO

Extending the Life of FPSO Installations: A Strategic Move for Sustainability and Structural Integrity

As the global energy sector accelerates toward a lower-carbon future, extending the operational life of existing offshore infrastructure—particularly FPSO units—has emerged as a critical strategy. This approach aligns with both environmental objectives and economic efficiency, enabling operators to meet evolving energy demands while minimizing the environmental footprint associated with new builds or premature decommissioning.

The Case for Life Extension

Today, approximately 55% of the global FPSO fleet is composed of converted oil tankers—vessels that have already consumed a significant portion of their design fatigue life during their previous service at sea. Factors such as sailing routes, cargo type, and operating conditions can dramatically influence the residual fatigue capacity of these hulls. When repurposed as FPSOs, these vessels are typically expected to operate for an additional 20 years or more—often under very different loading and environmental conditions.

This challenge is not limited to conversions. Even new builds (25%) and redeployments (20%) represent opportunities for structural optimization. With advances in fatigue management technologies—most notably Ultrasonic Peening (UP)—operators can now significantly enhance the fatigue performance of critical weld details, reduce long-term maintenance costs, and increase asset value and safety.

Moreover, a growing number of FPSOs worldwide have already surpassed their original design lives. For these units, structural life extension becomes essential. If such projects can be carried out in situ, avoiding the need for drydocking or towing to shipyards, the savings in time, cost, and carbon emissions can be substantial.

Fatigue: A Silent Limiter of Service Life

While corrosion is an important degradation mechanism in offshore environments, fatigue remains the primary constraint on structural service life, especially for floating assets subjected to continuous cyclic loading. In FPSOs, fatigue-critical welded connections include:

- Pallet stool welds to deck structures

- Bulkhead and web frame joints in ballast tanks

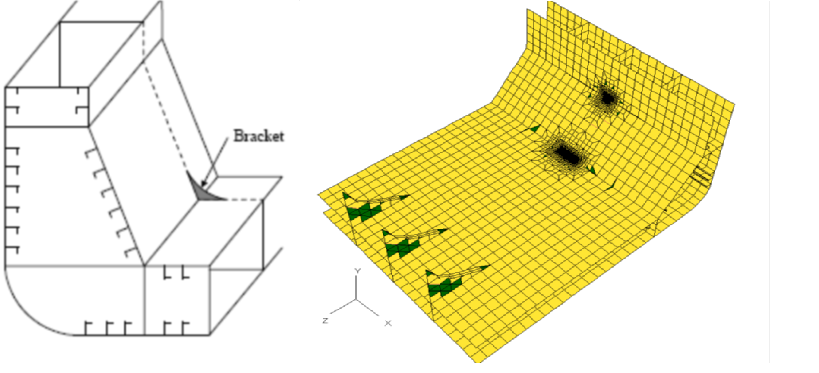

- Longitudinal bracket connections

- Hopper knuckle welds and scallops

- Tank bracket terminations and supports

These are often hidden yet essential structural details whose failure could compromise the integrity of the entire unit.

Ultrasonic Peening: A Proven Technology for Life Extension

Ultrasonic Peening (UP) is a mechanical surface enhancement technique that introduces compressive residual stresses at the weld toe, where fatigue cracks are most likely to initiate. The treatment delays or prevents crack initiation, effectively extending the fatigue life of the treated weld.

- ⏱️ 4x life extension for high-stress-range conditions

- 🔁 Up to 10x extension for moderate to low stress ranges

- ♻️ “Resets the clock” for welds that have consumed up to 50% of their fatigue life

- 🔧 Portable, quick, and non-invasive—ideal for on-location application

Fatigue test data, SN curves, and IIW recommendations all validate UP’s effectiveness. The method is especially impactful when applied to welds that have not yet developed visible cracks, making preventative treatment both viable and valuable.

Real-World Results

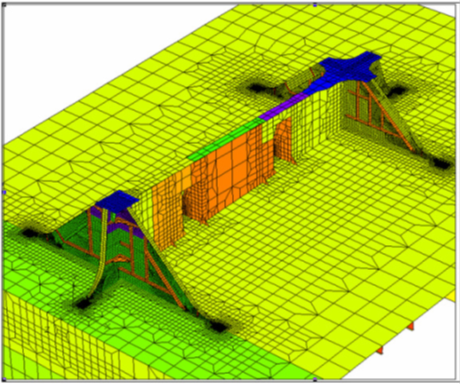

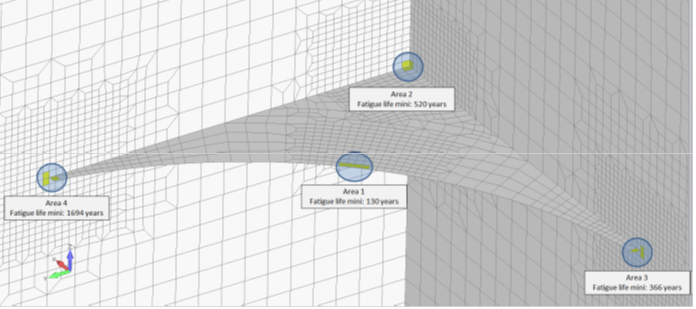

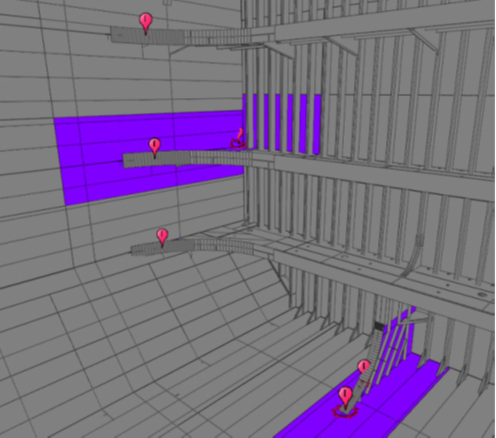

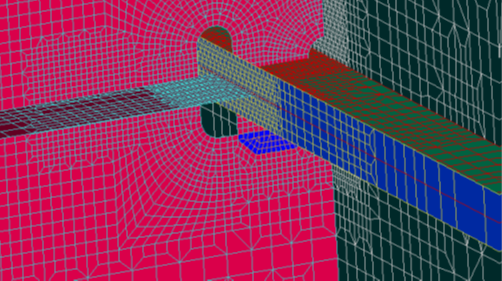

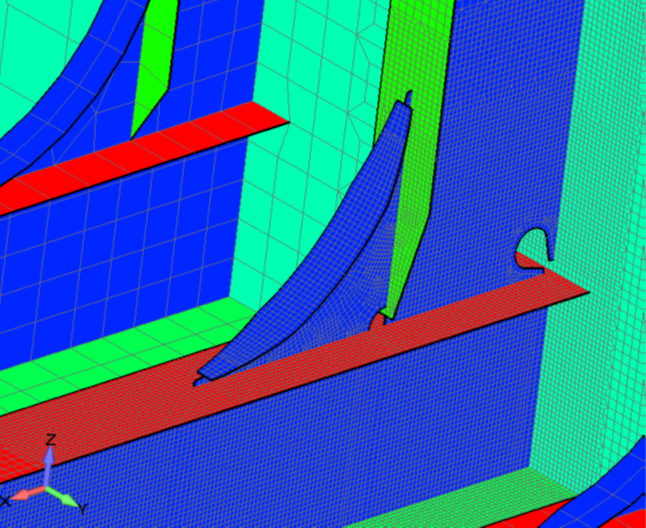

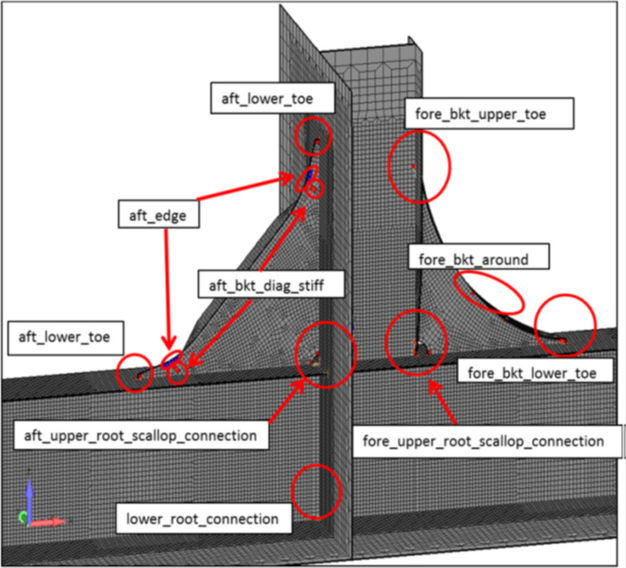

Since 2005, several offshore installations—including pilot projects on FPSO units—have implemented UP treatments on fatigue-sensitive welds identified through Finite Element Analysis (FEA). These analyses, conducted in collaboration with classification societies, revealed several weld details with predicted fatigue lives below the required service life.

Ultrasonic peening was applied to these locations as part of planned maintenance campaigns, avoiding costly drydockings. To date, treated welds from these early projects remain in excellent condition, showing no signs of crack initiation, even after years of continued operation under cyclic loading.

These successes have led to the adoption of standardized UP procedures for other critical locations on the same units, and the method is now widely accepted as part of life extension strategies for aging FPSOs.

Supporting a Greener Offshore Industry

Life extension of FPSO assets through technologies like Ultrasonic Peening directly supports the goals of the energy transition:

- 🌍 Reduced emissions by minimizing the need for new steel production and construction

- 🛠️ Less waste through repair over replacement

- 🌱 Lower carbon footprint from fewer shipyard mobilizations and drydock visits

- 🔋 Maximized use of existing energy infrastructure during the shift to a low-carbon economy

In today’s climate—marked by geopolitical instability, evolving energy demands, and increased scrutiny of environmental impact—life extension has become a strategic imperative. Operators recognize that maintaining and upgrading existing assets is often faster, more cost-effective, and far more sustainable than building new units from scratch.

Conclusion

With much of the FPSO fleet nearing or exceeding its design life, and new units taking years to develop, structural life extension has never been more relevant. Techniques such as Ultrasonic Peening offer a credible, certifiable, and field-tested method to enhance fatigue resistance, prolong service life, and optimize asset performance—all while supporting the industry’s transition toward a more sustainable future.

At LETS Global and MTL (Technical Limits), we are committed to delivering the tools, technologies, and expertise that make this transition both technically robust and economically viable.

🔗 Learn more at:

www.lets-global.com

www.technical-limits.com