CTOD Artic Environments

Materials for the Arctic

Introduction

Understanding CTOD and Weld Toughness

- Coarse-grained microstructures in the Heat-Affected Zone (HAZ)

- High residual tensile stresses

- Lack of post-weld heat treatment (PWHT)

- High constraint conditions near the weld root or cap

Ultrasonic Peening and Its Potential Role

- Reduce tensile residual stresses in the weld toe or surface region

- Delay crack initiation and growth

- Improve fatigue and potentially corrosion performance

Thermal Relaxation and the Limitation of Intermediate-Layer Peening

In multi-pass welds, the benefit of ultrasonic peening between passes is typically lost due to thermal relaxation. When a new weld pass is deposited, the previously treated layer experiences reheating. If the temperature of the previously peened layer exceeds about 200–300 °C, the compressive stresses and strain-induced dislocation structures relax almost completely.

Therefore:

- Intermediate-layer peening (between passes) provides limited or no lasting effect.

- Final-pass peening, performed after welding is complete and the joint has cooled below

~100 °C, is the most effective stage to preserve beneficial compressive stresses.

Air-Cooled Ultrasonic Peening System

LETS Global’s ultrasonic peening system is air-cooled, with continuous airflow through the tool and nozzle directed at the treated surface. This design can partially cool the weld surface during or immediately after welding.

Approximate Cooling Effect:

Assume:

- Airflow rate ≈ 0.05 kg/s

- Air temperature ≈ 25 °C

- Surface temperature after welding ≈ 500 °C

- Convective heat transfer coefficient ≈ 80 W/m²·K

- Local area treated ≈ 0.01 m²

The convective heat removal rate: Q = h · A · ΔT = 80 × 0.01 × (500 – 25) ≈ 380 W

This can reduce local surface temperature by approximately 150–200 °C in about 30–45 seconds, depending on material thickness and heat conduction.

Implication:

If ultrasonic peening is applied immediately after a pass while airflow continues, surface temperature might be brought down near the critical 250–300 °C threshold. In that case, partial retention of compressive stress and localized microstructural refinement could occur even before the next pass.

Verification would require:

– Infrared or thermocouple measurement of surface cooling rate

– Finite element simulation of thermal diffusion in the weld joint

Only if surface temperature remains below ~250 °C during and after peening can interpass peening be considered effective.

Review of Previous Studies on Ultrasonic Peening and CTOD

Several experimental studies have investigated how UP affects fracture toughness:

Zhou et al. (2008, J. Mater. Process. Technol.) – 7075-T6 Al alloy: CTOD ↑ 40% (0.12 mm → 0.17 mm); compressive stress ≈ 200 MPa.

Kim et al. (2011, Int. J. Fatigue) – Low-carbon steel: CTOD ↑ ~30% at –20 °C; compressive depth 0.3 mm.

Wang et al. (2016, J. Mater. Eng. Perform.) – Ti-6Al-4V: CTOD ↑ ~25%; microhardness +15%.

Liu et al. (2021, Metals) – Q345B steel: interpass peening reheated to 350 °C; CTOD reverted to baseline.

Conclusions:

- Peening increases CTOD only when residual compressive stresses remain intact.

- Thermal exposure >250–300 °C negates the improvement.

- Final-pass peening consistently shows benefits.

- The magnitude of CTOD gain is proportional to compressive stress amplitude and depth.

Application to Arctic Weldments

For Arctic or sub-Arctic applications (–40 °C and below):

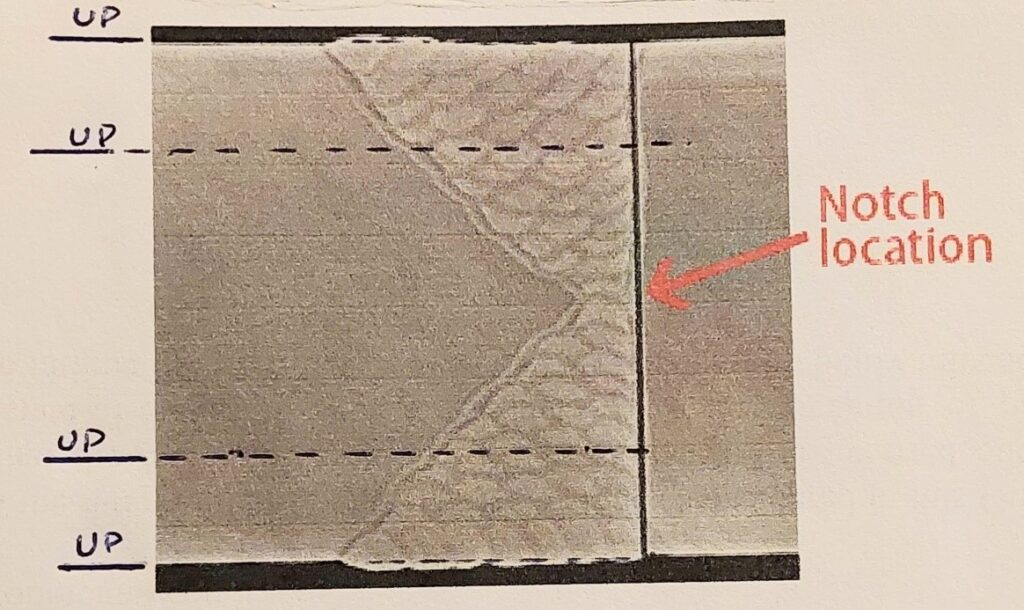

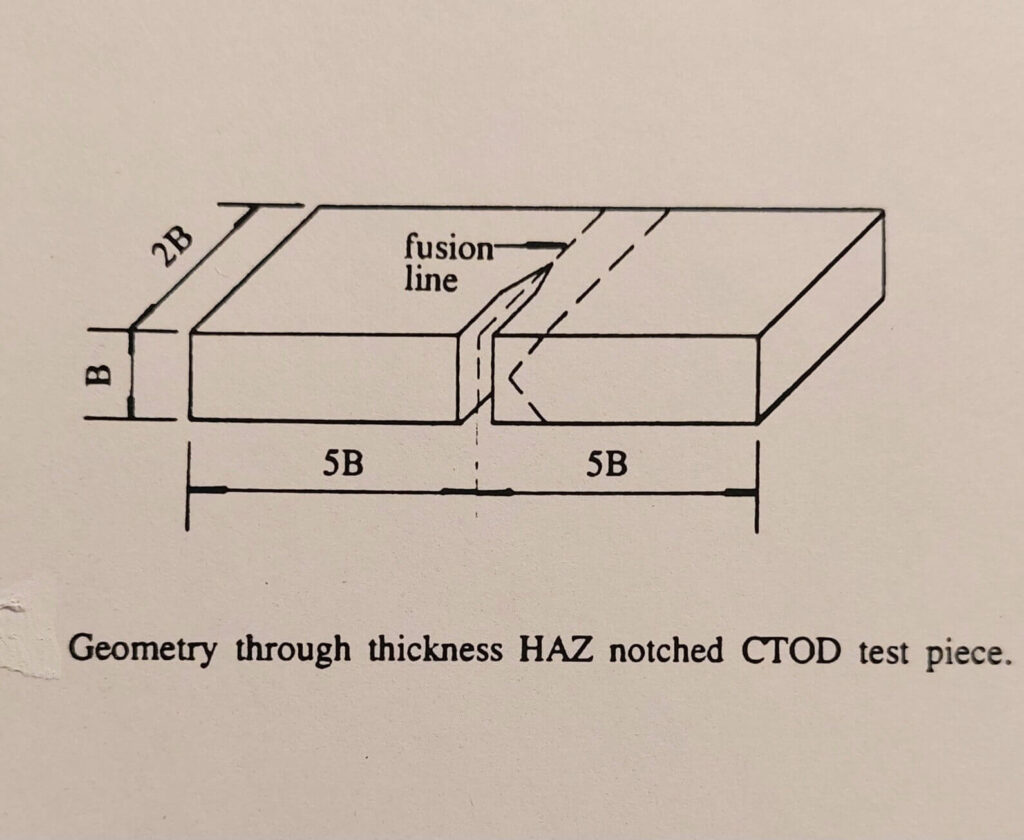

- CTOD testing is essential for verifying weld toughness.

- Typical acceptance criteria: CTOD ≥ 0.10 mm and Charpy V-Notch ≥ 27 J at –40 °C.

- Ultrasonic peening can enhance local weld toe performance if validated for the specific material and sequence.

Proposed Procedure for Thick-Plate Welds (≥ 50 mm)

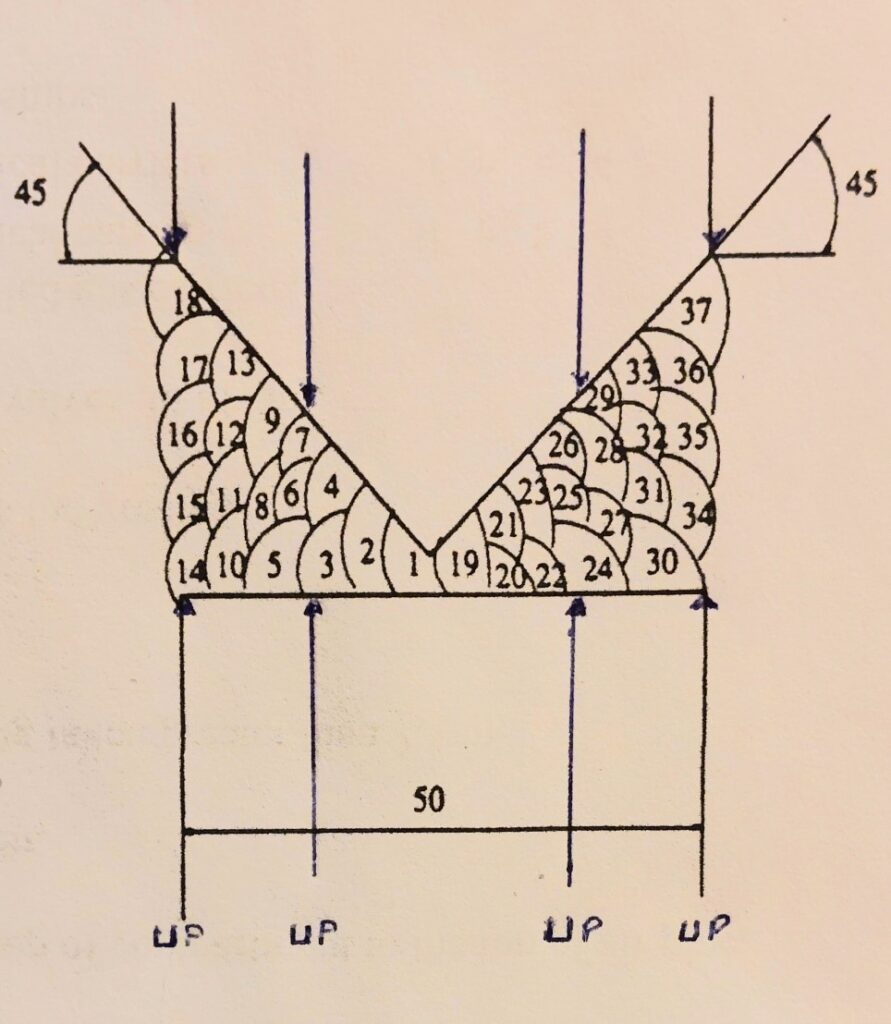

1. Deposit initial passes (~15 mm thickness).

2. Apply air-cooled ultrasonic peening immediately after each pass, maintaining airflow ≥ 0.05 kg/s.

3. Measure surface temperature: if below 250 °C, peening is valid; otherwise, only final pass peening is recommended.

4. After full weld completion, perform a final ultrasonic peening pass.

5. Extract CTOD specimens to confirm toughness gain.

Conclusions

Ultrasonic peening can improve CTOD by inducing compressive residual stresses and refining surface microstructure, but only when treated areas remain below critical relaxation temperatures. In multi-pass welds, intermediate peening is ineffective unless air-

cooling limits surface temperature below ~250 °C. LETS Global’s air-cooled system offers a potential solution, pending validation through thermal monitoring and CTOD testing.

Literature indicates 25–40% CTOD improvements in final-pass peening with compressive stresses around 150–250 MPa.

In summary, ultrasonic peening is a promising complementary technique for improving Arctic weldment performance, provided its thermal behavior is carefully controlled and verified by testing.