Pressure Vessels

Ultrasonic Peening in Pressure Vessels: Enhancing Fatigue Resistance, Safety, and Cost Efficiency

Introduction

Pressure vessels are vital components in industries such as petrochemical, power generation, and oil & gas. These vessels must withstand demanding operating conditions, including high pressures, fluctuating temperatures, and corrosive media. One of the most critical failure modes in pressure vessels is fatigue, which can be categorized as thermal fatigue, corrosion fatigue, or mechanical fatigue.

Welded joints, especially in areas like nozzle welds, are particularly susceptible due to geometric discontinuities and stress concentration. To mitigate this risk, ultrasonic peening (UP) has emerged as a highly effective method, capable of enhancing cyclic load resistance, extending service life, improving safety, and lowering costs.

Fatigue Improvement with Ultrasonic Peening

Residual Stress Redistribution

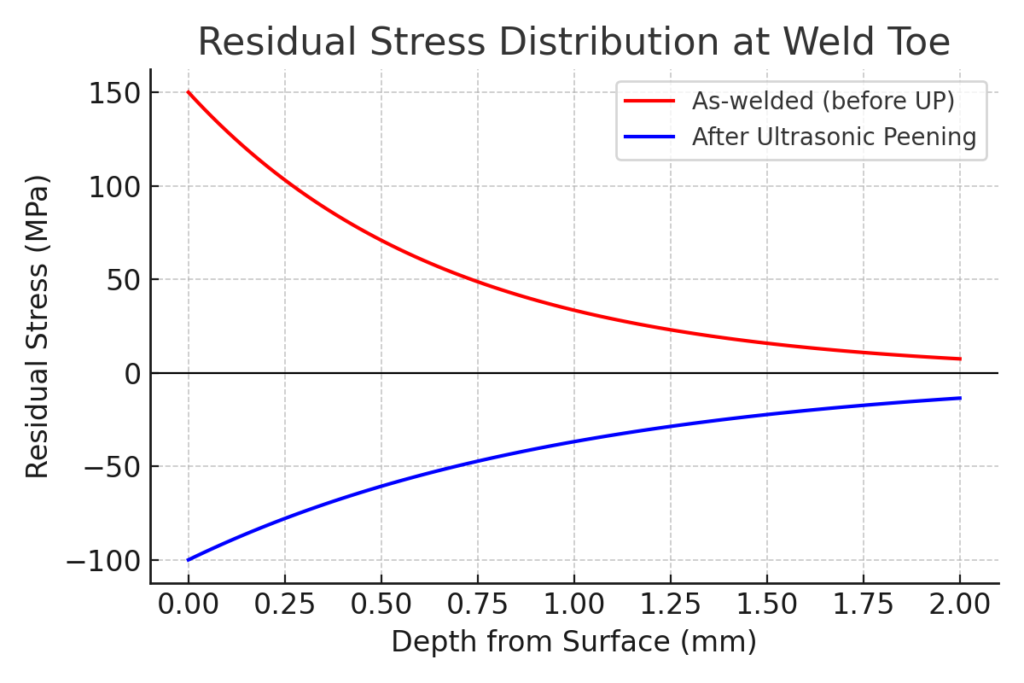

The core mechanism of ultrasonic peening lies in the introduction of compressive residual stresses at the weld toe and adjacent areas. This beneficial stress state counteracts the tensile residual stresses left by welding, which are responsible for crack initiation.

Before UP: Welded joints typically show tensile residual stresses near the weld toe, increasing fatigue crack risk.

After UP: Residual stress curves indicate a shift from tensile to compressive stresses, often reaching depths of 1–2 mm beneath the surface. This effectively delays crack nucleation and slows crack propagation.

Fatigue Life Extension: S–N Diagram Evidence

S–N (Stress vs. Number of Cycles) diagrams are a standard tool for evaluating fatigue performance.

As-welded joints: Show early failure under cyclic loading due to high local stresses.

UP-treated joints: The S–N curve shifts upward, reflecting longer fatigue life for the same stress amplitude.

Experimental studies report that ultrasonic peening can increase fatigue life by 2 to 5 times, depending on load levels and environmental conditions. For pressure vessels, this directly translates to higher reliability and fewer shutdowns. Increased Security and Reliability

Applying ultrasonic peening to critical welds in pressure vessels ensures:

– Lower probability of sudden rupture under cyclic stresses.

– Improved tolerance against crack growth in harsh service conditions (e.g., high temperatures, corrosive fluids).

– Enhanced structural reliability, a key factor for industries where vessel failure could result in catastrophic accidents.

In practice, ultrasonic peening significantly increases the safety margin of pressure vessels, aligning with both operational safety standards and regulatory requirements.

Cost Efficiency and Economical Calculus

From an economic standpoint, ultrasonic peening is highly cost-effective compared to alternatives such as weld redesign, thicker materials, or frequent replacements.

Example Calculation:

– Vessel without UP: Requires major repair after 10 years costing $200,000.

– Vessel with UP: Repair extended to 15 years, ultrasonic peening cost ≈ $30,000.

Cost without UP (20 years): 2 major repairs = $400,000.

Cost with UP (20 years): 1 repair ($200,000) + UP ($30,000) = $230,000.

Savings per vessel: $170,000 over 20 years.

For a facility with 10 vessels, cumulative savings exceed $1.7 million, not counting the avoided risks of catastrophic failure.

Conclusion

Ultrasonic peening offers a triple advantage for pressure vessel management:

1. Fatigue improvement through compressive residual stress redistribution and upward shifts in S–N curves.

2. Increased security, minimizing risks of fatigue failure in critical welds.

3. Cost efficiency, with measurable long-term savings supported by economic calculations.

By combining technical performance with strategic benefits, ultrasonic peening stands out as a best practice for extending the safe and economical operation of pressure vessels in demanding industries.