CTOD Artic Environments

Materials for the Arctic

Materials for the Arctic

Can the CTOD be improved by ultrasonic peening treatment?

Research showing the beneficial effect of ultrasonic peening on the CTOD of a material

There have been several studies conducted to investigate the effect of ultrasonic peening treatment on the CTOD of various materials. These studies have generally shown that ultrasonic peening treatment can significantly improve the CTOD of a material.

For example, a study published in the Journal of Materials Processing Technology in 2008, found that ultrasonic peening treatment was able to increase the CTOD of aluminum alloy by up to 40% compared to the untreated material. The study also found that the improvement in CTOD was directly related to the magnitude of the compressive residual stresses induced by the ultrasonic peening treatment.

Another study published in the International Journal of Fatigue in 2011, found that ultrasonic peening treatment was able to increase the CTOD of a low-carbon steel by up to 30% compared to the untreated material. The study also found that the improvement in CTOD was directly related to the depth of the compressive residual stresses induced by the ultrasonic peening treatment.

A study published in the Journal of Materials Engineering and Performance in 2016, found that ultrasonic peening treatment was able to increase the CTOD of a titanium alloy by up to 25% compared to the untreated material. The study also found that the improvement in CTOD was directly related to the magnitude and depth of the compressive residual stresses induced by the ultrasonic peening treatment.

In conclusion, these studies suggest that ultrasonic peening treatment can have a beneficial effect on the CTOD of a wide range of materials, including aluminum alloy, low-carbon steel and titanium alloy. The improvement in CTOD is directly related to the magnitude and depth of the compressive residual stresses induced by the ultrasonic peening treatment.

Is CTOD used for design weld in artic environment?

When is CTOD used to guarantee minimum toughness requirements for welds for artic climate conditions?

The frequency at which CTOD testing is performed to ensure minimum toughness requirements for welds used in arctic climate conditions will depend on the specific application and the regulations or standards that apply to it. It is usually done at the design stage and during production of the equipment. It is also often done as part of a quality control program, to ensure that the welds are meeting the required toughness standards throughout the life of the installation. It is also done at regular intervals to maintain the quality and safety. It is recommended to check with the relevant authorities or industry standards that apply to your specific application to determine the appropriate frequency of CTOD testing.

Is CTOD used to guarantee minimum toughness requirements for welds used in artic climate conditions?

What are the toughness requirement for a weld which will work at temperature -40 C?

The toughness requirement for a weld to work at a temperature of -40°C will depend on the specific application and the regulations or standards that apply to it. However, in general, the minimum requirement for a weld to be considered suitable for use at -40°C is typically a CTOD (Crack Tip Opening Displacement) value of at least 0.10 mm and a Charpy V-Notch impact energy value of at least 27 J at -40°C. The industry standards such as ISO, ASTM, and ASME have different set of requirements and guidelines that should be followed while designing and welding in such harsh environment.

Is ultrasonic peening currently used anywhere in the world in welded structures for artic environment?

Ultrasonic peening is a relatively new technology, and its use in welded structures for arctic environments is not very common. While some studies have shown that it may improve the toughness of welds, its applicability and effectiveness in arctic environments specifically depends on the specific application, the materials being used, and the conditions of the environment.

Ultrasonic peening is being researched as a method to improve the toughness of welds and other structures in cold or arctic environments, but it is not yet widely accepted or used in industry. It is considered as a research topic in most of the countries and its application is limited.

It is important to check with the relevant authorities or industry standards that apply to your specific application to determine if ultrasonic peening is an accepted method and if so, the appropriate guidelines to follow. Also, it is always good idea to consult with the experts in this field before applying this method to real-world application.

Ultrasonic peening procedure for CTOD testing for 500 mm and above.

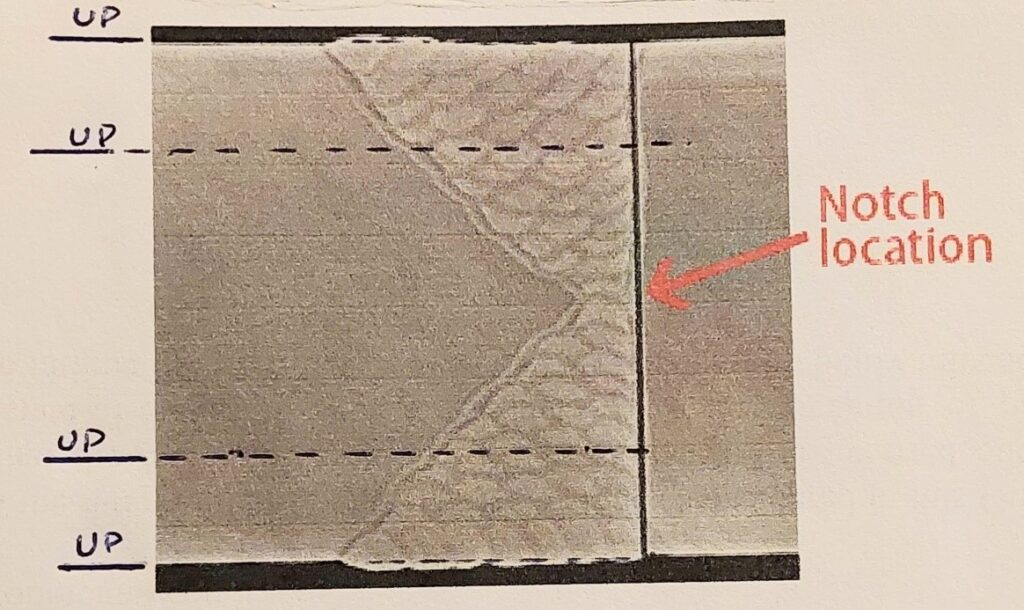

Welds of thickness 50 mm and above, are special sensitive for CTOD values since the thickness will induce considerable residual stresses when preheat and/or slow cooling possibilities are limited. Residual stresses of tensile character are known to have a negative influence on CTOD values. Furthermore, the application of traditional PWHT treatments is not only costly but in many situations is tedious or simply impractical.

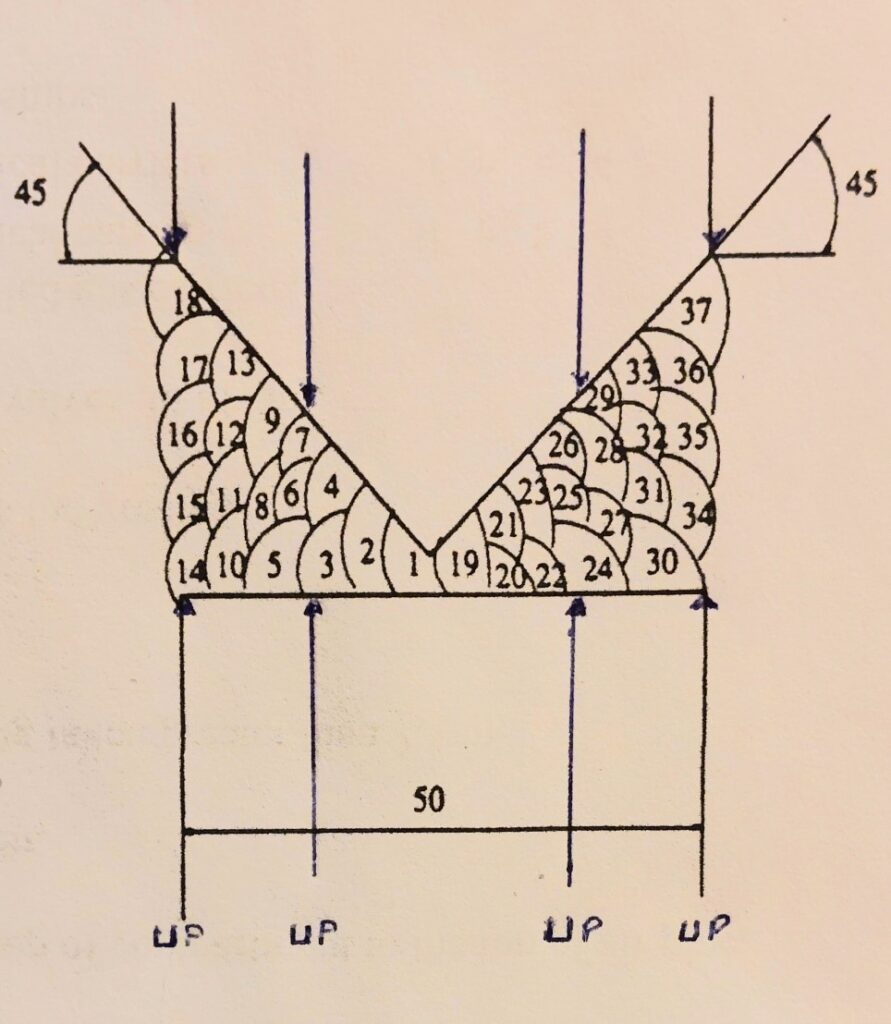

The ultrasonic peening treatment could be applied after a certain number of weld passes or a specific thickness is achieved. For example for a weld thickness of 50 mm the treatment could be applied after the first 15 mm weld deposit. After a subsequent weld layer of 15 mm, the ultrasonic peening treatment could be applied once more. The last ultrasonic peening treatment would be carried out after the last weld deposit or up to 50 mm thickness.

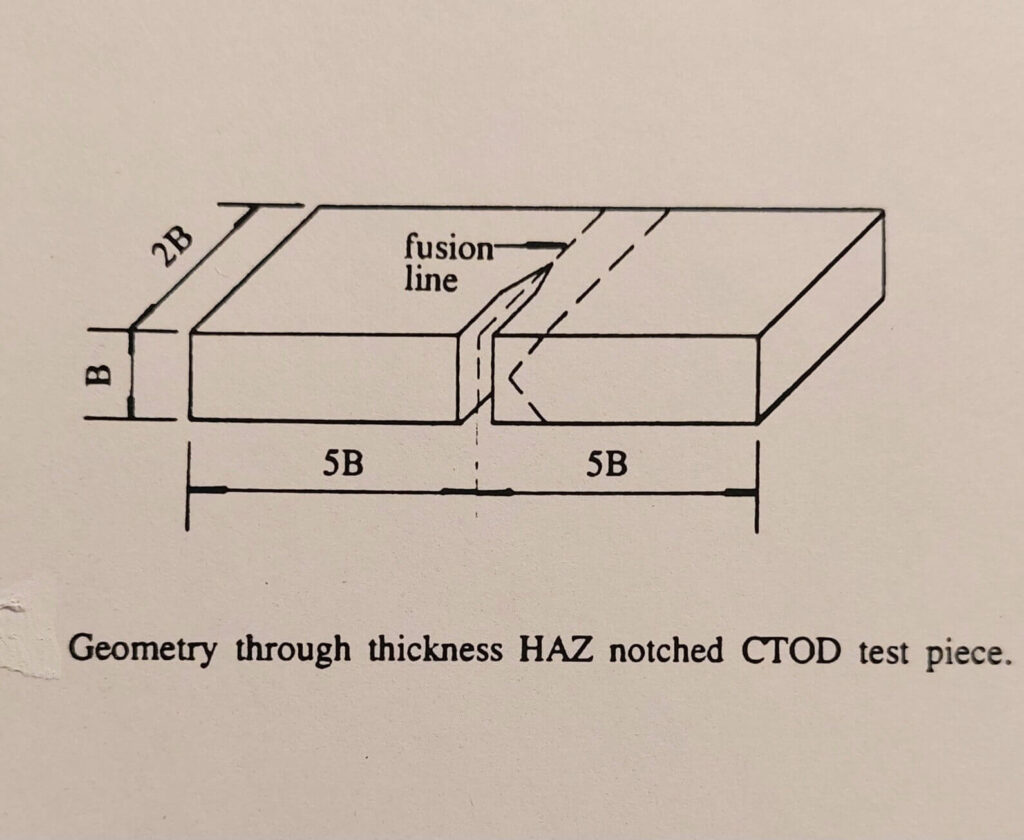

This procedure will ensure the application of compressive stresses though the entire thickness and as a result the tensile residual stresses will be relieved as the weld is completed. After this weld procedure is performed, including the ultrasonic peening, a CTOD test specimen can be manufactured and tested. As this procedure will likely demonstrate improved CTOD values the same procedure could be implemented in the workshop for the critical welds requiring special consideration in terms of CTOD values.